This week started off fairly leisurely as i attended (imo) the Southampton Yawnfest otherwise known as the Southampton Boat Show which highlighted in almost every way why sailing and boating is on an unstoppable decline here in the UK.

This week started off fairly leisurely as i attended (imo) the Southampton Yawnfest otherwise known as the Southampton Boat Show which highlighted in almost every way why sailing and boating is on an unstoppable decline here in the UK. For if the sheer indistinguishablility of nearly every boat there either power or sail didn't make you reach for the exits as well as the just insane costs that are new-boat prices it was the studied indifference; the almost aloofness of a good number of staff apparently wanting your business.

It absolutely beats the shit out of me and brings out my inner class-warrior; to see hoards of old white folk as well as the younger 'beautiful' people staring down their nose as you walk past, admittedly i am a long haired ginger with tattoo's down my arm's but what happened to the credo of everyone's a potential customer?

That was the first visit in about eight years and will probably be the last for the foreseeable future unless someone can design a sailboat that's not, a) the nautical equivilent of a Rover 75 or b) a floating homage to the Korean Car Industry.

Moving on, this week can best be described as 'challenging' having got very well acquainted with my former i'd built the previous Saturday then rebuilt twice this last week..........bored!

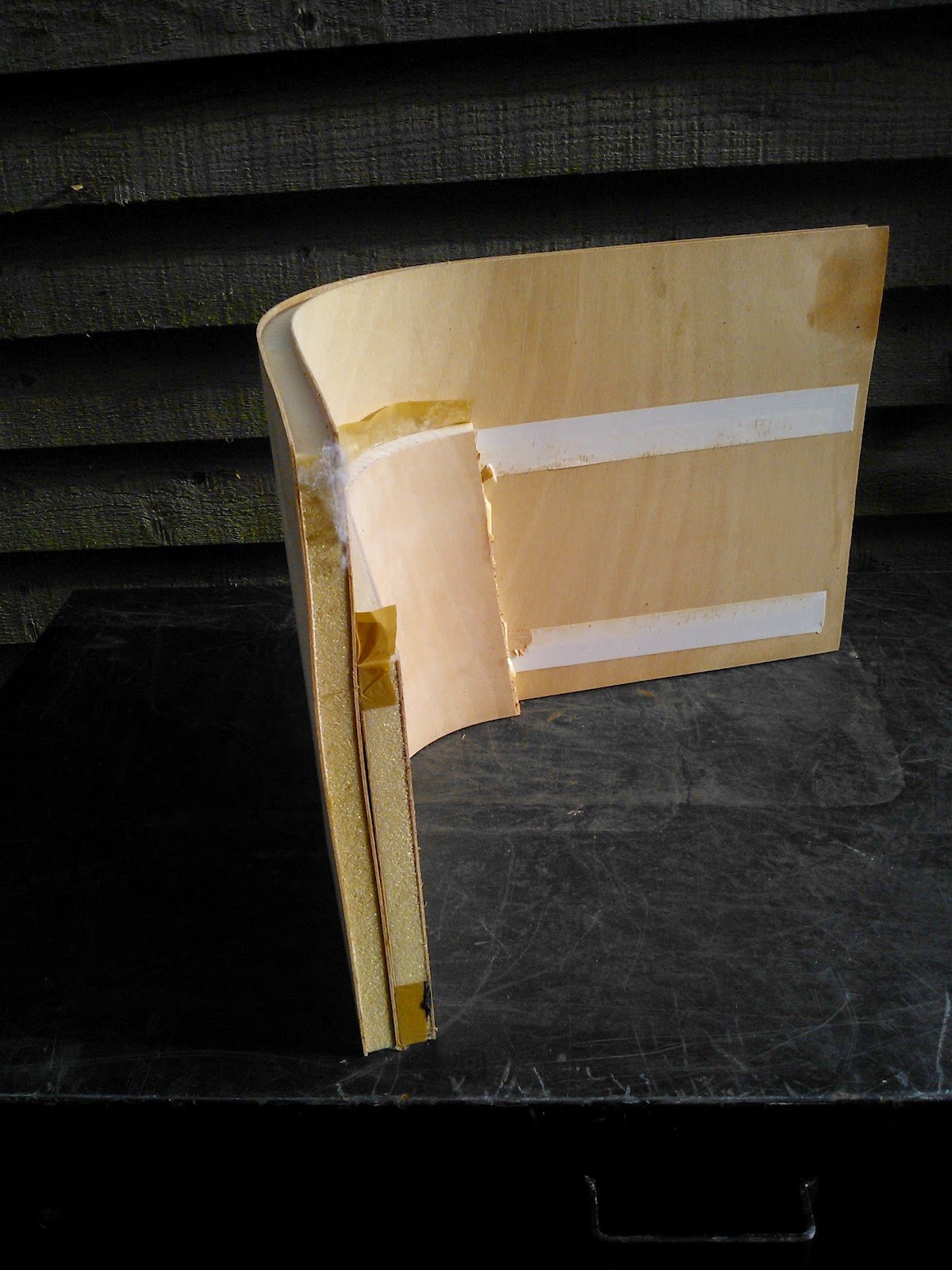

Moving on, this week can best be described as 'challenging' having got very well acquainted with my former i'd built the previous Saturday then rebuilt twice this last week..........bored!I've learnt this week that industrial-strength double sided tape appears to have a much higher bonding strength than epoxy! I know, i'm baffled by it too but its cost me a heap of time and money finding out that fact.

After one side of the form imploded at the first attempt at a stupidly low pressure i later found out after i'd put additional stiffeners in i'd broken its back too which created a less than perfect outcome but one thats salvageable.

So the goal next week is to start bonding all this into the hull, i cut back the floor grid so i can get a perfect lamination down the inside front of the settee berth and onto the hull, i'm err-ing more to the MK1 Griffon approach of a large pull out to make the double berth.

I've got a 100m roll of oak capping coming too as i dug out all the oak then realised how much time and effort would be needed to run it out to 2 - 3mm plus not possessing a band saw would make this job way more arduous using a table saw so thought it more prudent seeing how much time i've lost this week.